B&A Rifle Final Plans

- Acdcmonkey1991

- Specialist 3

- Posts: 386

- Joined: Fri Mar 30, 2007 3:33 pm

- Location: Florida

This is the FINAL design for the cannon/rifle I'm building this weekend. Instead of the old design, the chamber is now 3 in. X 12 in. At 150 PSI the GGDT says I can get 106 foot pounds and 550 fps with a 50 gram projectile. The valve is a modified sprinkler with a 1/4 in. ball valve actuator. The barrel is 30 in. long and is shc. 40 3/4 in. PVC. It is now also a muzzle loader due to its raw power.

- Attachments

-

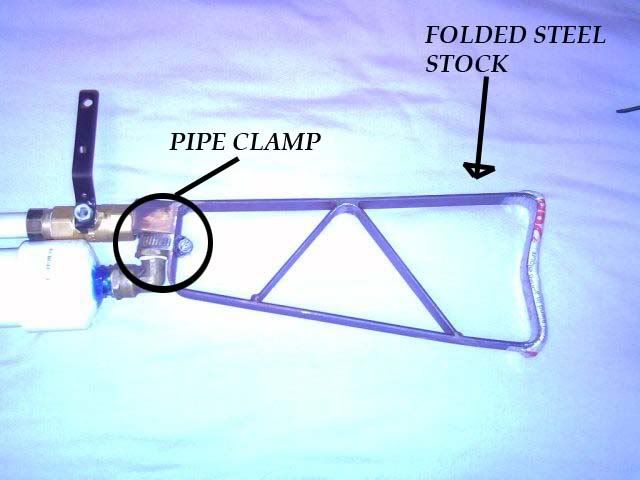

- This is the old...

- riflesz.JPG (24.46 KiB) Viewed 2474 times

-

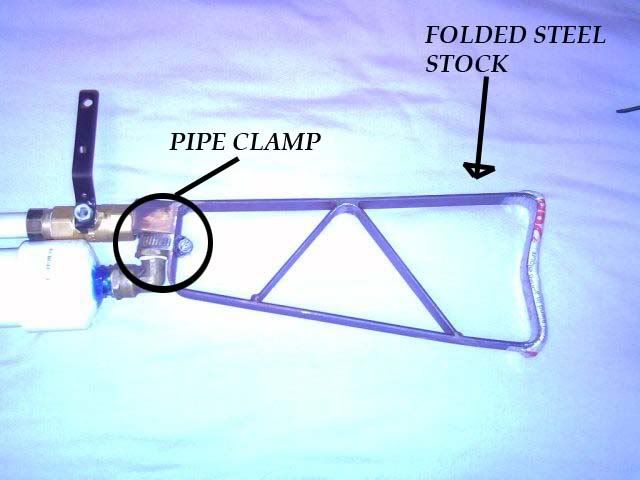

- This is the new...

Notice the new stock design and the safety valve - rifle model.JPG (17.45 KiB) Viewed 2474 times

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

There will be some dead space in that design. How bout you bridge the upper and lower parts of the stock and plug the rest.

- spudthug

- Corporal 5

- Posts: 936

- Joined: Mon Feb 26, 2007 9:02 pm

- Location: johnsonburg, Pa USA

- Contact:

that dead space wont matter because the valve is at the barrel...if the valve was at the chamber isnt that dead space??? (i know i am probly wrong but thats always what i thought) yell at me if u want but thats what i thought...maybe (most likely) im wrong...correct me

4" piston valved cannon-half done..( i spilt my cement...)

Hybrid- 75% done. need to build propane holder and drill/tap sparkplug hole..

Hybrid- 75% done. need to build propane holder and drill/tap sparkplug hole..

- Acdcmonkey1991

- Specialist 3

- Posts: 386

- Joined: Fri Mar 30, 2007 3:33 pm

- Location: Florida

I'm probably going to cut a custom piece of wood to put in between the sock and then glue it in between.

No, you're right.

Dead space is empty space that has to be pressurised by the released gas before it reaches the projectile.

There shouldn't be a problem with having the stock pressurised.

Dead space is empty space that has to be pressurised by the released gas before it reaches the projectile.

There shouldn't be a problem with having the stock pressurised.

Flow restriction might be a factor, it would be more economical to take the shortest route, such as from the chamber, 2 x 90° elbows, then to the valve, and attach a stock on the back, like so........

or similar.

good luck.

skinner

or similar.

good luck.

skinner

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

spudthug wrote:that dead space wont matter because the valve is at the barrel...if the valve was at the chamber isnt that dead space??? (i know i am probly wrong but thats always what i thought) yell at me if u want but thats what i thought...maybe (most likely) im wrong...correct me

You're right. I'm not all there sometimes.

- Acdcmonkey1991

- Specialist 3

- Posts: 386

- Joined: Fri Mar 30, 2007 3:33 pm

- Location: Florida

The stock is actually part of the tank.

Create an account or sign in to join the discussion

You need to be a member in order to post a reply

Create an account

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute

Sign in

-

- Similar Topics

- Replies

- Views

- Last post

-

- 15 Replies

- 3574 Views

-

Last post by starman

-

- 16 Replies

- 7367 Views

-

Last post by Pyro Ninja

-

- 16 Replies

- 5751 Views

-

Last post by john bunsenburner

-

- 28 Replies

- 10045 Views

-

Last post by BonziPon

-

- 53 Replies

- 16708 Views

-

Last post by Flash